Steam and Gas Turbine Inspection Services

Unmatched precision and reliability — our steam and gas turbine inspections catch issues before they cost you millions.

Our Comprehensive Turbine Inspection Services

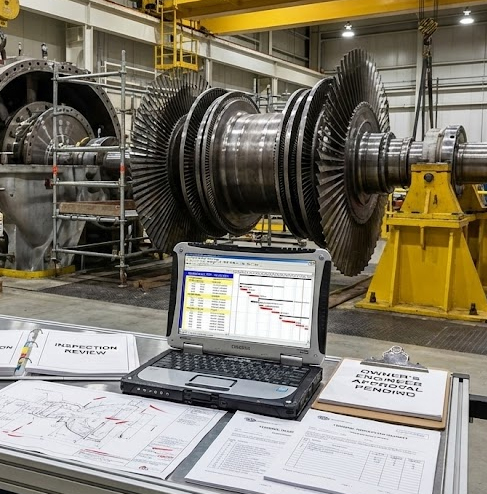

Advanced Turbine Support brings unmatched expertise to every assessment project. Our approach combines technical excellence with practical operational knowledge. Power plants benefit from our comprehensive understanding of equipment operation. We identify potential issues before they impact performance.

Inspection

Services

Our services include, but are not limited to:

We develop and validate exclusive inspection services based on fleet emergent issues.

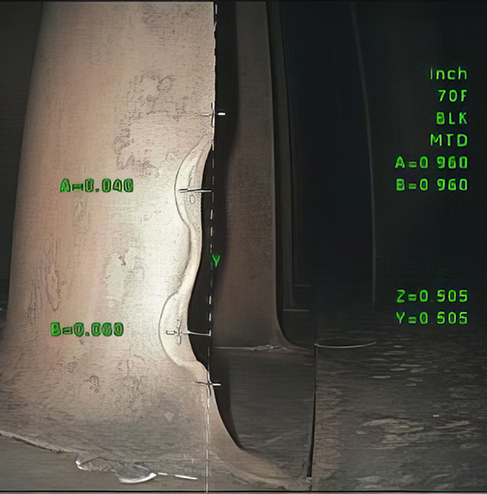

Here at Advanced Turbine Support, we strive to issue a final report within 24 hours of the inspection’s completion. Results are discussed with the site contact prior to inspector’s departure. This timely service and commitment to our customers saves millions of dollars in lost availability and maintenance costs. From combustion turbine services to steam turbine services and much more, our state of the art equipment will help identify any problems that may be affecting your machines.

Specialty inspections include, but are not limited to:

Contact a Representative

Protect your investment and prevent costly downtime — contact our turbine inspection experts today for fast, reliable results.