Major Inspections

Advanced Turbine Support delivers comprehensive major inspection services for steam and gas turbines—giving owners clear visibility into asset condition, repair risk, and next-step decisions when stakes are highest.

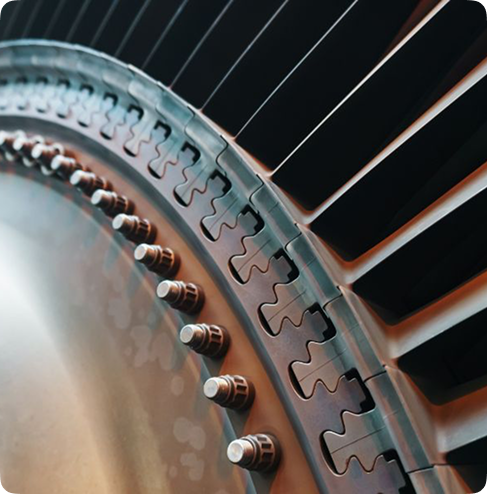

Rotating Components

Rotating components carry the highest consequence of failure—and the smallest defects can have outsized impact. Our rotating component inspections focus on identifying cracks, wear, distortion, and material degradation before they threaten reliability.

Inspection focus includes:

- Turbine rotors and shafts

- Discs, wheels, and blade attachments

- Critical transition areas prone to fatigue and cracking

- Dimensional and surface condition verification

Stationary Component Inspections

Stationary components often hide damage that escalates quietly until performance drops or forced outages occur. We inspect high-risk stationary components to confirm integrity, alignment, and remaining life.

Inspection scope includes:

- Nozzles, diaphragms, and vanes

- Casings, partitions, and support structures

- Erosion, corrosion, cracking, and deformation

- Fit-up and condition relative to OEM limits

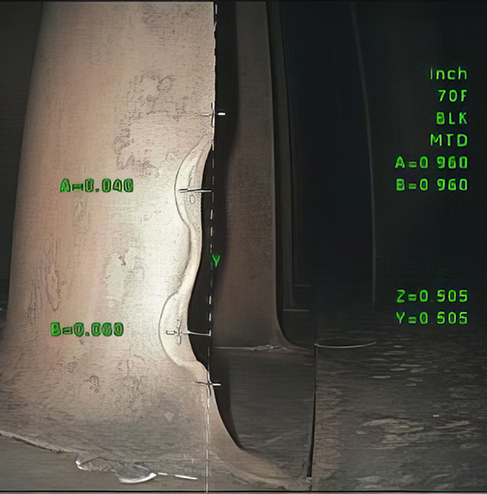

Compressor & Turbine Casing NDE

Casing integrity is foundational to safe operation and proper alignment. Our non-destructive examination services identify hidden flaws without introducing unnecessary risk or disassembly.

NDE methods may include:

- Magnetic Particle Inspection (MPI)

- Dye Penetrant Inspection (DPI)

- Ultrasonic Testing (UT)

- Visual and dimensional verification

Bearing Inspections

Bearings are often early indicators of deeper mechanical or alignment issues. We inspect bearing components to identify wear patterns, distress, and lubrication-related damage before failures propagate.

Bearing inspection coverage:

- Journal and thrust bearings

- Surface condition and wear assessment

- Alignment and load-related indicators

- Lubrication and contamination evidence

Quaternary Cleanings

Clean components reveal the truth. Our quaternary cleaning process removes deposits, oils, and contaminants to ensure inspections are accurate—not masked by residue.

Cleaning supports:

- Improved defect visibility

- More accurate NDE results

- Better documentation and reporting

- Reduced false positives or missed damage

Why Major Inspections Matter

Trusted Gas Turbine Inspection Specialists

Find Problems Early

Identify defects before they escalate into forced outages

Validate Repair Scope

Separate necessary work from unnecessary recommendations

Protect Your Schedule

Avoid late discoveries that derail outage timelines

Make Defensible Decisions

Inspection results you can stand behind

Aeroderivative maintenance

Inspections That Drive Better Decisions — Not Just Reports

Major inspections shouldn’t leave you sorting through data without direction. Our approach focuses on translating inspection findings into clear, actionable guidance—so you understand what matters, what doesn’t, and what can safely wait. That clarity prevents unnecessary work and keeps your outage plan grounded in real risk.

We help you distinguish between cosmetic findings and conditions that truly threaten reliability or schedule. By tying inspection results to operating history, failure modes, and OEM criteria, we provide context that supports confident repair decisions—not reactive ones driven by uncertainty.

The outcome is fewer last-minute scope changes, tighter cost control, and inspections that actually support execution. When work begins, you’re not guessing—you’re moving forward with a plan backed by evidence and experience.

Certifications & Qualifications

Gallery

Engineering support

See how thorough inspections, proven methods, and field-tested execution reveal hidden risk and protect your outage before work begins.

World's Best Gas

and Steam Turbine

Inspection Company

Don't Let Critical Findings surface too late

If you’re planning a major outage or preparing for inspection-driven decisions, now is the time to bring in experienced turbine inspectors who understand consequence, risk, and execution realities. Early involvement helps identify critical issues before timelines tighten and costs escalate. The result is clearer priorities, fewer surprises, and inspection findings you can confidently act on when it matters most.