Non-Destructive Evaluation (NDE) Testing Services

Advanced non-destructive evaluation services designed to detect hidden defects, validate component integrity, and support confident repair decisions—without damaging critical turbine assets.

In-Situ Dye Penetrant Inspection (DPI)

In-situ dye penetrant inspection is a proven method for identifying surface-breaking defects without component removal. Our technicians perform DPI in the field to uncover cracks, porosity, and surface flaws that could otherwise go undetected.

Common applications include:

- Blade roots and attachments

- Welded areas and fillets

- High-stress transition zones

- Surface condition verification prior to repair

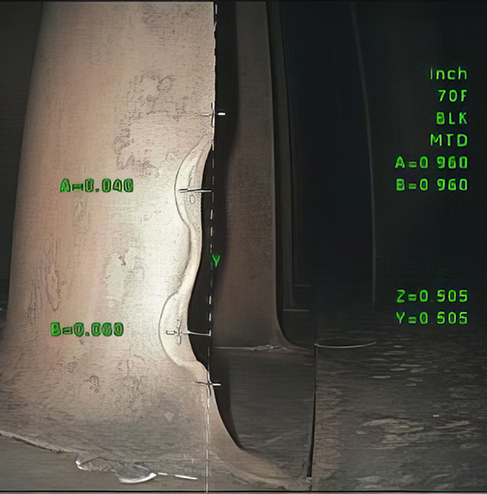

Eddy Current Testing (ECT)

Eddy current testing allows us to detect surface and near-surface defects in conductive materials with high sensitivity. This method is ideal for identifying early-stage cracking in areas where visual inspection alone is insufficient.

ECT is commonly used for:

- Blade dovetails and attachments

- Rotor and disc surfaces

- Heat-affected zones

- Detection of fatigue and stress cracking

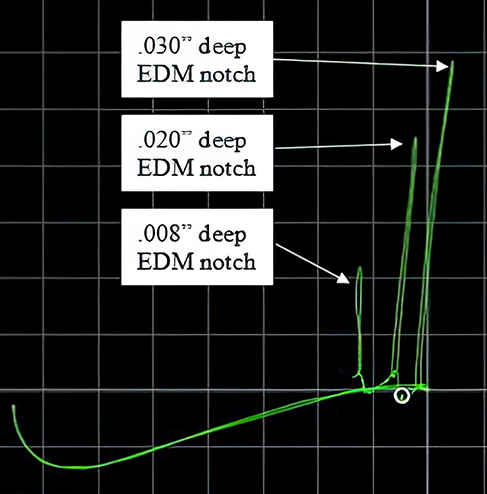

Phased Array Ultrasonic Testing (PAUT)

Phased array ultrasonic testing provides advanced subsurface inspection capabilities, allowing precise flaw detection and sizing within critical components. PAUT delivers detailed imaging that supports engineering assessment and repair planning.

PAUT advantages include:

- Detection of internal flaws and discontinuities

- Accurate defect sizing and depth analysis

- Reduced inspection time with expanded coverage

- Data-driven evaluation for repair decisions

Magnetic Particle Inspection (MPI)

Magnetic particle inspection is an effective method for identifying surface and near-surface discontinuities in ferromagnetic materials. MPI is widely used to confirm crack presence in high-stress components.

Typical MPI applications include:

- Shafts, rotors, and couplings

- Casings and bolted joints

- Keyways and threaded areas

- Post-cleaning and post-repair verification

Why Non-Destructive Testing Matters

Trusted Gas Turbine Inspection Specialists

Detect Hidden Defects

Identify flaws before they lead to failure

Improve Inspection Accuracy

Go beyond visual inspection limitations

Support Confident Decisions

Provide data that guides repair scope

Protect Reliability

Reduce forced outage and safety risk

Non-Destructive Evaluations

NDE Testing That Drives Better Decisions — Not Just Data

Non-destructive evaluation should do more than confirm that an indication exists—it should help you decide what to do next. Our NDE testing is performed with outage execution, repair planning, and operational risk in mind, ensuring results are relevant, accurate, and immediately usable.

We combine advanced inspection technologies with turbine-specific experience to put findings into context. This allows us to separate minor, non-actionable indications from defects that truly threaten reliability, safety, or schedule—before those decisions become expensive.

The outcome is inspection data you can trust when it matters most. With clearer priorities and defensible results, teams gain tighter scope control, fewer late-stage surprises, and confidence moving forward with repair or continued operation.

Certifications & Qualifications

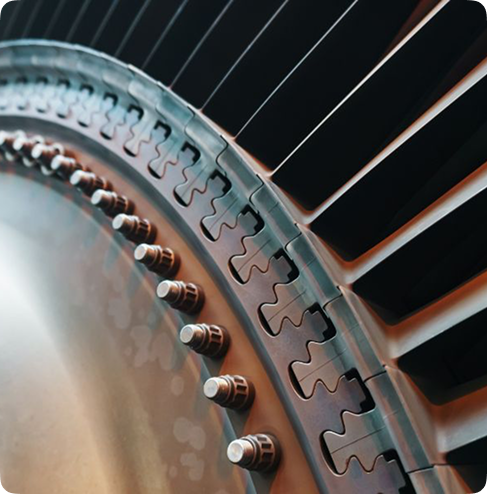

Gallery

NDE Testing

A closer look at advanced NDE methods in action—revealing critical defects, validating component integrity, and supporting high-stakes turbine decisions.

World's Best Gas

and Steam Turbine

Inspection Company

Get Clear Answers Before Decisions Are Locked In

If you’re preparing for a major inspection, evaluating repair options, or managing turbine risk, now is the time to bring in experienced NDE professionals. Accurate testing today prevents costly consequences tomorrow.