Owner's engineer Repair management

Ensure every repair performed during your turbine outage is justified, executed correctly, and aligned with your long-term operational strategy—not vendor sales objectives. Our Owner’s Engineer Repair Management services provide unbiased engineering oversight that protects your equipment, budget, and outage schedule.

What Is Owner’s Engineer Repair Management?

Repair management is the independent oversight of all turbine repairs performed during an outage. Instead of allowing OEMs or contractors to define what gets replaced or reworked, we verify each action against real inspection data, OEM tolerances, and lifecycle objectives—ensuring repairs support asset integrity rather than vendor margin.

Why Repair Decisions Need Independent Oversight

During an outage, repair recommendations often escalate quickly—from optional to urgent—without measurable justification. Our Owner’s Engineers verify findings, confirm damage mechanisms, and challenge unnecessary additions to scope. This prevents budget creep, avoids downtime surprises, and ensures every repair directly supports turbine reliability.

Where Repair Management Delivers Its Greatest Value

The most expensive outage decisions occur at the point of inspection review. We validate repair proposals, assess NDE results, confirm proper tolerances, and ensure contractors follow correct repair sequencing. By catching issues before execution, we eliminate rework, protect the critical path, and prevent irreversible mistakes.

How the Owner’s Engineer Controls Cost & Quality

Without oversight, repairs can proceed without evidence, pricing checks, or conformance verification. We enforce acceptance criteria, review vendor documentation, validate material selection, and confirm workmanship meets OEM and industry standards—delivering repairs you can trust, not question.

The Lifecycle Advantage of Independent Repair Verification

Turbine repairs affect more than the outage—they shape future availability, efficiency, and inspection intervals. We document findings, run-life projections, and component history so each repair becomes part of a lifecycle strategy, not a disconnected outage expense.

WHY CHOOSE ADVANCED TURBINE SUPPORT FOR Owner's Engineer REPAIR MANAGEMENT

Why Advanced Turbine Support Can Help

Independent Advocacy

We represent the owner’s interests—not OEMs, contractors, or vendors.

Unmatched Turbine Expertise

Decades of steam and combustion turbine outage experience driving decisions.

Condition-Based Decisions

Repair scopes driven by real turbine condition, not assumptions.

Predictable Schedules

Our oversight eliminates avoidable downtime and scope-based delays.

Condition-based risk analysis

COMPREHENSIVE OWNER’S ENGINEER REPAIR MANAGEMENT SERVICES

Our repair management process delivers independent oversight that ensures every repair is necessary, properly executed, and aligned with your turbine’s long-term performance goals—not vendor-driven priorities.

We provide:

- Repair Scope Verification — Confirm only required repairs move forward

- Technical Quality Oversight — Validate all work meets OEM specifications

- Lifecycle Documentation — Record repairs for future outage planning

The result is proven repair integrity, controlled spending, and a turbine that performs reliably long after the outage ends.

Certifications

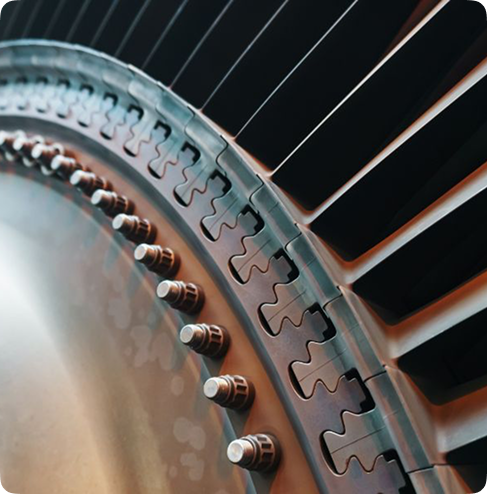

Gallery

CBRE

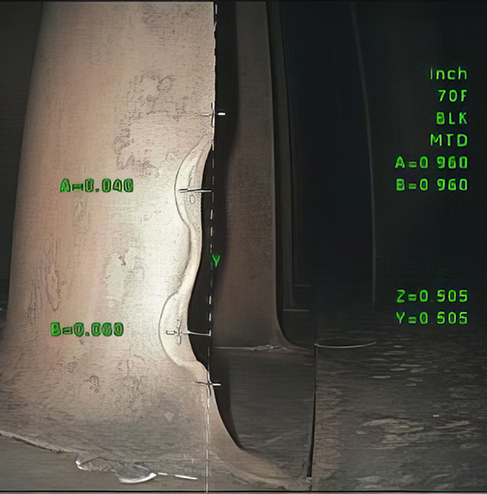

At Advanced Turbine Support, every dye penetrant test represents our commitment to uncovering the smallest surface flaws with precision, ensuring your equipment operates safely and reliably under any condition.

World's Best Gas

and Steam Turbine

Inspection Company

SCHEDULE OWNER’S ENGINEER REPAIR MANAGEMENT SERVICES

Take control of your repair decisions before they become expensive liabilities. Partner with Advanced Turbine Support and ensure every repair performed during your outage is justified, compliant, and aligned with your operational priorities.