Steam Turbine Inspection Services

Experienced steam turbine subject matter experts plan & manage inspections, outages & repairs.

Comprehensive Steam Turbine Inspection, engineering evaluation, & repair management

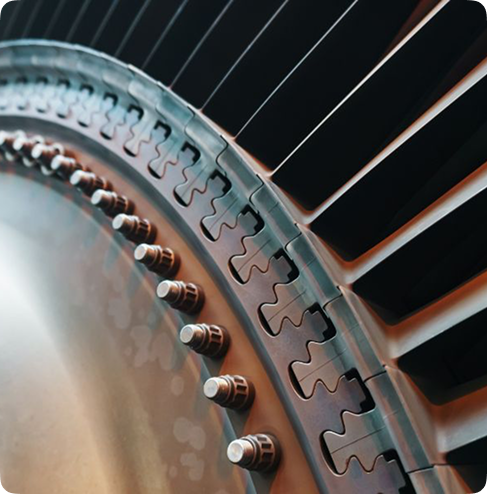

Your steam turbine is one of the most critical assets in your operation. Regular inspection and maintenance are essential to ensure peak performance, avoid costly outages, and extend equipment lifespan.

At Advanced Turbine Support, our certified specialists deliver complete steam turbine inspection services — including repair, testing, and diagnostics — backed by decades of industry experience. From on-site field service to major overhauls, we provide cost-effective solutions that minimize downtime and improve overall efficiency.

Inspection Solutions for Industrial steam turbines

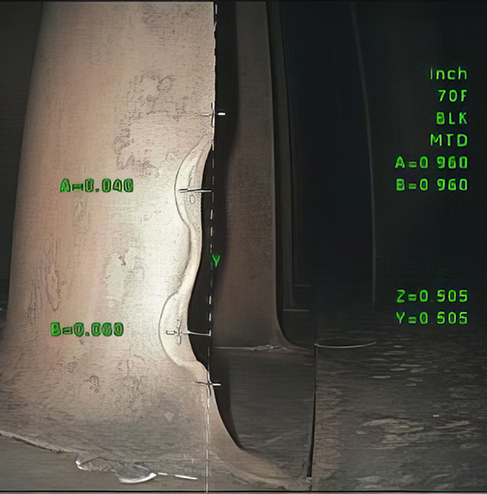

Our inspection services are trusted by industrial and energy clients worldwide. Using advanced borescope technology, our team performs both in-situ and open casing inspections to assess the steam path at select locations without full disassembly.

Capabilities include:

- In-Situ Inspection: On-site, Borescope & L-0 & non-destructive evaluation

- Valves: Visual & non-destructive evaluation

- Steam Path Evaluation: Assessment of Rotor, blades, Diaphragms & Casings.

- Valve & Seal Testing: Identification of leaks, erosion, or performance degradation.

Every inspection concludes with a detailed condition report delivered within 24 hours, giving operators immediate visibility into the system’s condition.

Field Service engineering Capabilities

Owners engineer support provided by our team of experts with a focus on Quality & Repair Schedule Transparency.

Capabilities include:

-

Outage Management/Oversight – Providing on-site outage process oversight, to ensure critical to quality process steps are adhered to and documented for historical reference.

-

Repair Management/Oversight – Providing repair shop guidance and oversight, to ensure schedule transparency and repair process quality is adhered to.

Steam turbine maintenance / outage planning

Detailed maintenance & repair planning to include repair budgets and contingency risks to prepare for.

Maintenance solutions include:

-

Unit Maintenance History Review – Evaluation of previous unit history, supporting major outage refurbishment plans.

-

Maintenance/Outage Plans – Detailed unit inspection and refurbishment recommendations categorized by risk factors evaluating maintenance history / steam path condition / age & service duty requirements.

Inspection technology

Advanced Turbine Support utilized high-resolution borescope and NDE equipment and processes. To most effectively inspect and evaluate the health of your steam path components.

Advanced Inspection Offerings:

- Borescope

- Non-Destructive Testing

- (FMT) Fluorescent Magnetic Particle Inspection

- (UT) Ultra Sonic

- (PT) Penetrant

- (PAUT) Phased Array Ultra Sonic

- (EC) Eddy Current

Why Choose Advanced Turbine Support

Trusted Specialists in Steam Power Equipment Inspection and Repair

Comprehensive Inspection Services

On-site and open casing evaluations using advanced diagnostics.

Expert Repair Services

Advanced Technology

High-resolution borescope tools for precise inspection and reduced downtime.

Field Service Capabilities

Global response for emergency support and scheduled maintenance.

Steam Turbine inspections

reliabiilty centered life cycle management support

The Advanced Turbine Support engineering team has developed a diligently structured lifecycle management approach, aimed at maximizing unit reliability.

Our Steampath Inspections, Maintenance History Review, Service Duty Requirement Evaluations support our Engineering teams risk assessments and recommendations.

Experienced Engineers, Rapid Reporting

Our experienced engineers understand that downtime costs can reach millions per day. That’s why we deliver every inspection report within 24 hours of completion—giving operators immediate visibility into their turbine’s condition.

We maintain inspection teams strategically located across North America, ensuring fast mobilization for emergency inspection & field service support request, worldwide.

Certifications

Gallery

steam turbine inspections

World's Best Gas

and Steam Turbine

Inspection Company

Schedule Your Hot Gas Path Inspection Today

When you need dependable gas turbine maintenance, trust the experts at Advanced Turbine Support. Our team performs every hot gas path inspection with precision, care, and efficiency—helping you extend turbine life, optimize performance, and prevent costly failures.

Contact us today to schedule your next hot gas path or combustion inspection and keep your operation running safely and efficiently.